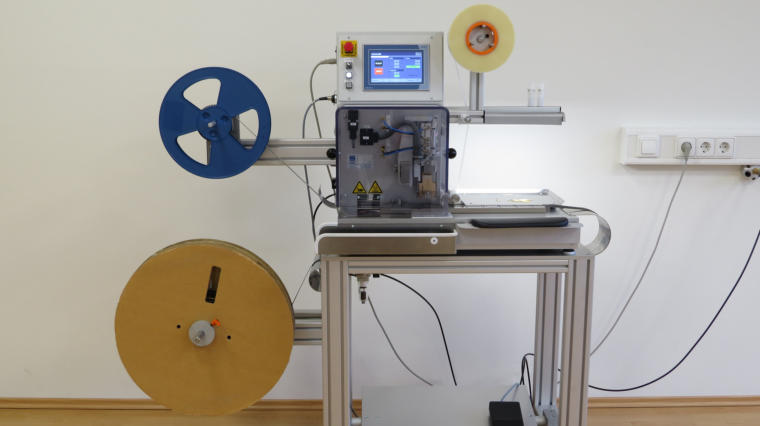

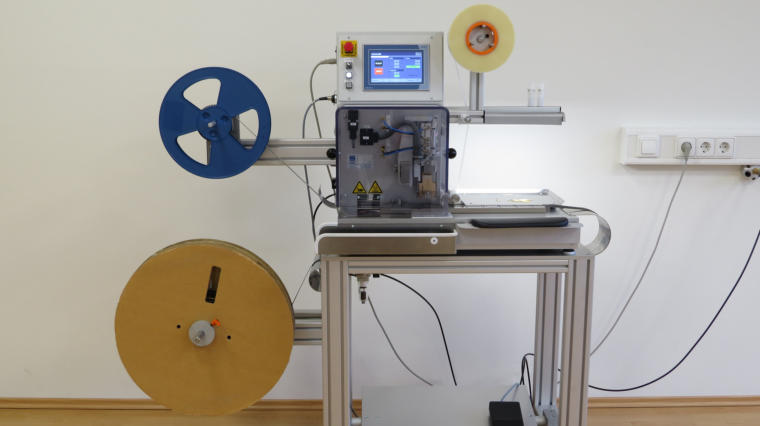

Blister taping machines

SGM 100

Taping machine (table design) for packaging SMD components or

other small mechanical parts by hand or from a placement machine.

•

Tape width 8 to 72 mm, pocket depth 14 mm (standard)

•

Special version up to 120 mm tape width and 25 mm pocket

thickness

•

Reel diameters: 560 mm unwinding, 330 mm winding

•

Output manual placement: up to 1500 parts/hour (parts-

dependent)

•

Output automatic placement: up to 4000 parts/hour

•

Easy conversion to another device / tape width

•

Hot sealing device or cold sealing device

•

Electric drive (step motor)

•

SABO-PLC with 7 inch color display (since February 2013)

•

Control by foot switch or automatic feed selectable

•

Adjustable parameters: feeding in 4 mm steps, nominal

quantity, leader length, trailer length, hot sealing time,

pressure, and temperature, tolerance of sealing temperature,

cycle time of automatic feeding, automatic cutting, test stripe,

counting over pockets

•

Interface to placement machine for integration into production

line

•

Modular construction

•

Custom design possible

•

Option: cutting device --> automatic tape cutting

•

Option: component control at insert position

•

Option: control, whether component was inserted correctly

•

Option: mark inspection device

•

Option: ESD design

•

Option: machine table

•

Option: save function for various programs

•

Height: 700 mm

•

Width: 480 mm

•

Length (without arms /with arms): 700 mm / 1400 mm

•

Weight: approx. 50 kg

•

Operation voltage: 230V

•

Air supply: 6 bar (for hot sealing and cutting device)

Tape turned around

(controller up to date)

With unwinding arm (latest

controller: see ‘tape turned around’)

With belt hopper (latest

controller: see ‘tape turned around’)

Blister taping machines

SGM 100

Taping machine (table design) for packaging SMD components or

other small mechanical parts by hand or from a placement machine.

•

Tape width 8 to 72 mm, pocket thickness 14 mm (standard)

•

Special version up to 120 mm tape width and 25 mm pocket

thickness

•

Reel diameters: 560 mm unwinding, 330 mm winding

•

Output manual placement: up to 1,500 parts/hour (parts-

dependent)

•

Output automatic placement: up to 4,000 parts/hour

•

Easy conversion to another device / tape width

•

Hot sealing device or cold sealing device

•

Electric drive (step motor)

•

SABO-SPS with 7 inch color display (since February 2013)

•

Control by foot switch or automatic feed selectable

•

Adjustable parameters: feeding in 4 mm steps, nominal

quantity, leader length, trailer length, hot sealing time,

pressure, and temperature, tolerance of sealing temperature,

cycle time of automatic feeding, automatic cutting, test stripe,

counting over pockets

•

Interface to placement machine for integration into production

line

•

Modular construction

•

Custom design possible

•

Option: cutting device --> automatic tape cutting

•

Option: component control at insert position

•

Option: control, whether component was inserted correctly

•

Option: mark inspection device

•

Option: ESD version

•

Option: machine table

•

Option: save function for various programs

•

Height: 700 mm

•

Width: 480 mm

•

Length (without arms /with arms): 700 mm / 1,400 mm

•

Weight: approx. 50 kg

•

Operation voltage: 230V

•

Air supply: 6 bar (for hot sealing and cutting device)

Special application:

•

In combination with component preparation, consisting of ...

o

Blister taping machine

o

Tool sets for component processing

o

Component feeding

o

Height-adjustable and rollable worktable

o

ESD version

Combined with component

preparation