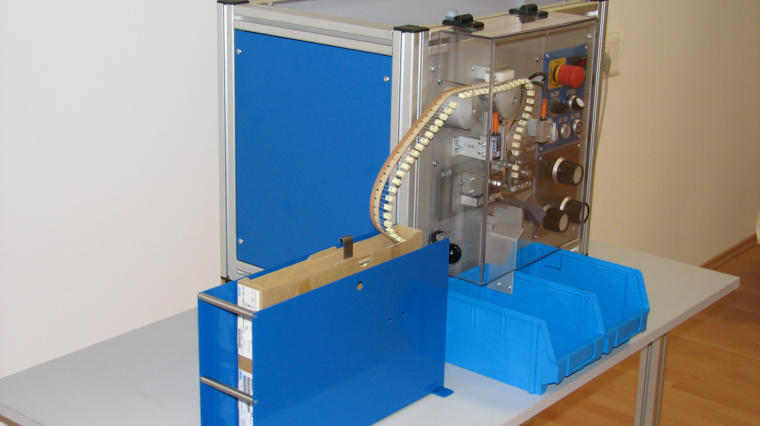

Radial component

preparation machine

RA 200

Cutting, bending and crimping machine for the processing of electronic components with radial leads, feeding from tape. Machine description: • Suitable for radial components that are taped in grid 12.7 mm (=½ inch) • Standard tools for cutting, cutting-bending, and cutting- bending-crimping • Bending forms: snap-in, standoff • Tools as customized versions available • Tools made with carbide to guarantee high durability • Tools are driven by cam discs • Component body is always tension released during processing • Minimal pressure marks on the wire • Lead diameters: 0.4 - 0.9 mm • Pin length and crimping deepness are infinitely adjustable • The central position of the tools to the components (leads) are infinitely adjustable as well • Mentioned settings can be adjusted via turning knobs (located at the front of the machine) • Component pitch 12.7 mm (½”) • Tape hole pitch 12.7 mm (½”), alternatively 15.0 mm • Easy exchange of tools to another component type possible within a few minutes • Cutting tool for shredding the tape (optional available) • Output: up to 8000 components/hour (depending on tape quality, lead diameter, and processing method) • Electronic counter • Machine switches off automatically under the following conditions: nominal pieces reached, end of or failure in tape (overload protection) • Transparent protective cover, ESD optional • Electric drive (three-phase motor) • Operation voltage: 230V/50Hz (standard), other voltages are available on demand • Power consumption: max. 450 W • Length x width x height (without accessories): 970 x 660 x 540 mm • Weight: approx. 45 kg (without accessories)