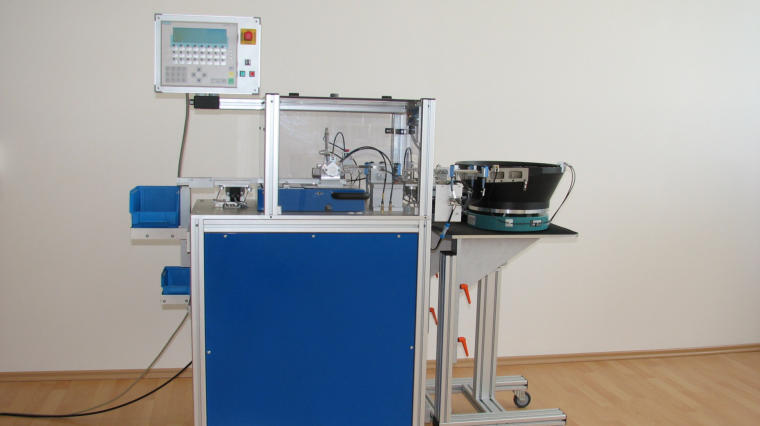

Radial component

preparation machine

LBM 110

Cutting, bending and crimping machine for the processing of electronic components with radial leads, feeding from - stacks - vibration bowl - tape - hand (by small capacity) Machine description: • Standard OR customized tools / bending forms • Processing of bicolored LEDs with component diameter up to 11 mm with 2 or 3 PINs (Option: LEDs bicolor) • Feeding options for LEDs: Component feeder without test and turning device OR component feeder with test and turning device (without color detection) • Defective LEDs are automatically sorted out (without color testing) • Tools for processing electrolytic capacitors (only from tape possible) • Tools made with carbide to guarantee high durability • Tools are driven by cam discs • Component body is always tension released during processing • Minimal pressure marks on the wire • Lead diameters: 0.4 - 1.3 mm • Pin length and crimping deepness are infinitely adjustable • Component pitch 25.4 mm (1”) or 12.7 mm (½”) • Tape hole pitch 12.7 mm (½”), alternatively 15.0 mm • Easy exchange of tools to another component type possible within a few minutes • Cutting tool for shredding the tape (optional available) • Output: up to 4000 components/hour (depending on component and processing) • PLC Biviator or alternativley Siemens S7 controller; different parameters adjustable; plain text display • Transparent protective cover, ESD optional • Electric drive (three-phase motor) • Power consumption: max. 900 W • Operation voltage: 230V/50Hz (standard), other voltages are available on demand • Air supply: 6 bar by pneumatic demand • Length x width x height (without accessories): 1600 x 800 x 1500 mm • Weight: approx. 120 kg (without accessories)

LED

E-Cap

Tape